Volumetric or gravimetric dosing

For volumetric weighing the number of revolutions determines the dosing. There are different options for determining how many revolutions the screw must make. Van Beek measures how much product comes out of the screw per revolution and then it is clear how many revolutions are needed to achieve the required quantity. We then adjust the screw for this.

For products with good running qualities this is often accurate enough, but for example in the case of sticky products such as flour gravimetric weighing is preferable. A weighing belt then measures the weight of the packaging while the dosing screw fills it up. The weighing belt sends a signal to the screw as soon as the required weight is reached.

Instead of the weight of the packaging the weight of the dosing installation can also be weighed (Loss in Weight, LIW). The loss in weight of the installation then determines the dosing.

Also suitable for products with poor running qualities

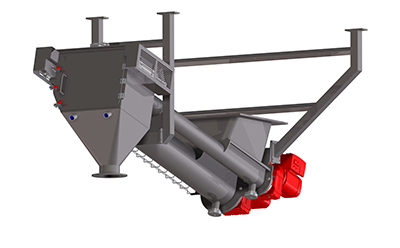

A useful extension for products with poor running qualities is a stirrer. This has its own drive operating at a fixed speed. For example the screw is filled to the optimum which is certainly important in volumetric applications. The dosing accuracy is then maintained and reproducible.

Refill valve also an option

Another possible option is a pneumatically operated refill valve. This shuts off the screw outlet as soon as the required weight is reached.

Very fast and yet accurate

Van Beek also has a solution for very fast and yet accurate filling of large packagings: the double dosing screw. A large screw brings the weight for example to 19.5 kilo and then stops. A smaller screw continues running and fills it to the required weight of for example 20 kilos.

Can be used anywhere

A dosing screw can offer a solution for every conceivable process where a controlled feed is necessary. Van Beek dosing screws are used for example in wastewater treatment plants to add flocculant, in the food industry to add salt, sugar or herbs and in brick factories to add colourant for bricks.

SpeedClean, SS and ATEX all possible

Screw dosing systems can be made of steel or SS304, SS316 and there is also an ATEX version. Van Beek can also make the screw removable for very fast cleaning, inspection or replacement with a different screw with which the dosing range can be widely adjusted with the same machine.

As a kitchen aid

Van Beek has a number of standard models for common situations. Many adjustments can be made to these models, such as the screw they contain. Many things can also be added such as the refill valve, a bigger buffer hopper and a stirrer. Our sales engineer Peter Verhoeven likes to describe the screw as a big kitchen aid with which you can do all sorts of things. He would be pleased to talk to you if you have any questions about the use of a dosing screw in your process.