Van Beek Sr. built on a unique screw roller, composed of materials that he had collected from demolition yards. A truck gearbox, bearings from a tram and gearwheels from a tank. Untrained and without any theoretical knowledge he constructed a colossal innovation, thought up entirely on his own.

Experience, skill and a real inventor’s spirit drove him to go on experimenting for 20 years on this complicated machine with a unique application. His screw roller was revolutionary, from then on it was possible to roll strip steel endlessly around a tube. The ribbon wrapped so tightly round it that welding was the only way to produce a screw fit for purpose. As far as we know Van Beek is still the only company in Europe to master this production technique.

You will understand that there is no manual to show you how to operate this complex machine. The knowhow about this screw roller (and a second smaller roller that Mr Van Beek Sr. built later) was passed on by the master from 1974 via the oral tradition to Dick de Rooij. Today Dick de Rooij still works for Van Beek and because of his specialist knowhow is the man for screw rollers. Last year Dick, now 59 years old, with justifiable pride, celebrated his 40th anniversary, which means that during his career he has already rolled over 1.5 million metres of screw.’

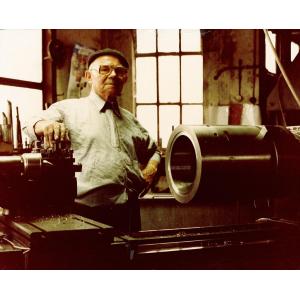

If you visit Dick in the factory you will hear the roller ‘screaming’ from far off. As you get closer you can smell hot metal and oil in the air. Dick is the current master of this roller, a unique craftsmanship that he clearly exercises with passion.

Dick still remembers old Mr Van Beek well. As a young lad he was able to assist him in his work and experiments. “As long as you didn’t make any comments, it was fine” says Dick. “Van Beek Sr. did not tolerate any input or contradiction. He was a man of few words and always busy. There was in fact no question of collaboration, so I had to find out or try most things myself to learn how to carry out rolling.”

After 40 years, rolling is still a challenge for Dick “Rolling is unpredictable, the slightest thing can put the roller out. This may happen by just the door opening and the ambient temperature falling. The heads then cool slightly and the pitch (distance between two screw blades) immediately increases, so I have to constantly watch out and make adjustments.”

Van Beek started up in 1939 as a craftsman’s workshop and grew over 75 years into an innovative market leader in Europe in the field of screw conveyors and screw heat exchangers. If you would like to come and see the screw roller and meet Dick, you are warmly welcome for a tour round our factory. See with your own eyes the contrast between the old screw rollers and a high-tech test centre. You will be amazed at the synergy between the past, present and future.